Key takeaways:

- How does construction slowdown affect cities and businesses? It results in delayed decisions, increased rework, and budget overruns.

- What role does AI play in construction project management? AI analyzes data to predict delays, flags risks, and optimizes schedules, helping teams make timely decisions.

- What are key benefits of AI in construction? AI enhances safety, improves communication, ensures predictable schedules, and flags risks earlier.

- How does AI support construction site safety? AI enhances safety through wearables, drones, and real-time monitoring for hazards and compliance.

- Is AI replacing human workers in construction? No, AI supports human workers by automating repetitive tasks and improving processes, but human oversight is key.

What happens when construction slows down? Everything slows down. When construction projects run smoothly, cities expand, businesses open, and families move in. When it doesn’t, you feel it in slow decisions and mounting rework that quietly drags the budget off course.

But even with construction’s central role in daily life, the sector is wrestling with a familiar stack of pressures. Labor is harder to find, and an aging workforce makes the gap tougher to close. Safety remains a constant concern in one of the most hazardous industries, and material costs swing with supply chain disruptions and tariffs. Meanwhile, inconsistent project management and scattered communication make managing construction projects an uphill battle.

AI isn’t here to replace crews. It’s here to shrink the gap between noticing a problem and acting on it, so teams spend more time making decisions that protect the schedule.

Role of AI in modern construction

You may be thinking AI sounds out of place in a hands-on industry, but McKinsey reports that large construction projects typically run 20% longer than scheduled and up to 80% over budget.

In construction project planning and management, AI can analyze historical project data to predict delays, flag risks early, and recommend more efficient schedules. Machine-learning forecasting is especially useful for calling out repeat bottlenecks, so construction project managers can adjust sequencing or resourcing before the schedule takes the hit.

Even on the job site, AI is showing up in multiple ways. Everything from drones and robotics to machine learning and virtual tools helps teams compare plans and coordinate changes faster, which comes with many benefits.

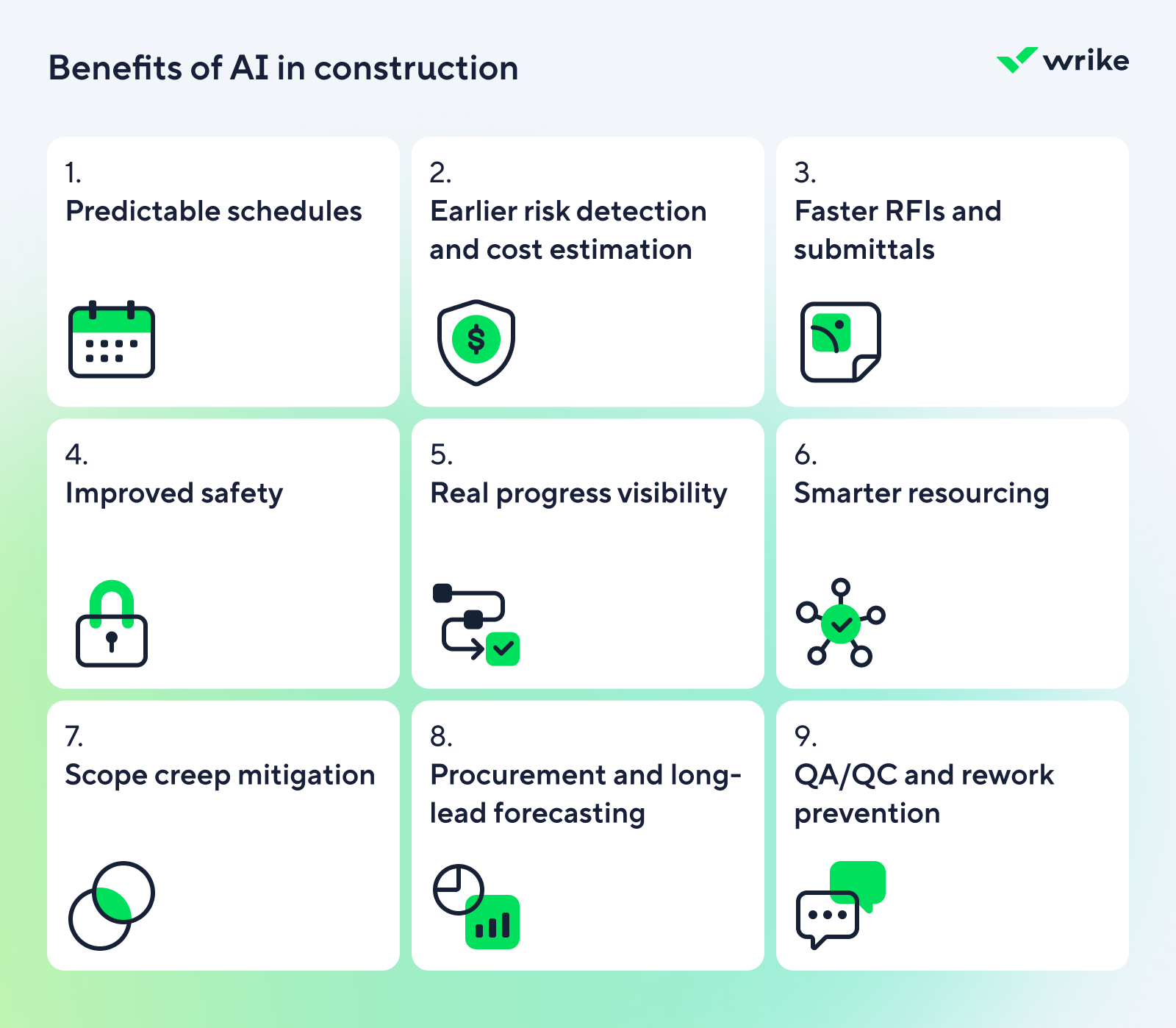

Benefits of AI in construction

Construction projects generate more information than any one person can track, and that reality isn’t changing. AI is already showing up across a broad range of construction projects.

If your goal is to effectively run construction projects, leveraging AI provides construction project managers with earlier and clearer signals across the work.

Predictable schedules

AI makes schedules more predictable by identifying where time will be lost before it lands on the critical path. It learns patterns from your past jobs and compares them to what’s happening now, across a broad range of signals like RFIs/submittals cycling, long-lead items drifting, inspection rework, or productivity falling below baseline.

Earlier risk detection and cost estimation

AI can scan the signals you already generate across construction projects, such as production rates, submittals, change activity, procurement lead times, and rework trends. It then flags the patterns that tend to precede project delays and cost overruns.

This way, you get earlier warnings tied directly to project costs, scope, and schedule.

Faster RFIs and submittals

The benefit here is speed with fewer unforced errors. When you’re using AI, you stop fumbling for RFIs (requests for information) and submittals across specs, drawings, emails, and someone’s memory. Construction project managers can use AI-powered project management tools built on large language models to draft clearer RFIs and extract the most relevant context from project documents.

On the submittal side, AI can help generate submittal logs and flag likely missing submittals by reading specs, but it still needs a quick human check before it drives procurement.

Improved safety

In 2023, about 20.8% of U.S. workplace deaths occurred in the construction industry, making it one of the most dangerous industries to work in.

AI is improving site safety through:

- Wearables that detect fatigue and proximity risks

- Equipment telematics that flag unsafe operation patterns

- Drones that spot potential safety hazards in hard-to-reach areas

- Tools that mine daily logs and near-miss reports to surface repeat risk patterns

They can even use computer vision to monitor construction sites in real time and flag missing personal protective equipment (PPE), which is proving to be a practical way to automate safety-related compliance processes at construction sites.

Real progress visibility

AI helps turn scattered field updates into a clear picture of where the job really stands. Photos, videos, and drone footage from the site can be analyzed and compared against the latest drawings or BIM model to flag what’s out of place or out of sequence.

Instead of waiting for the next site walk, OAC meeting, or end-of-month report, construction project managers get more frequent, accurate updates on what’s installed, what’s still open, and what’s blocked, down to specific areas and scopes. Add machine learning to spot drift from plan, so you can address slippage before it shows up as a schedule hit.

Smarter resourcing

Smarter resourcing is where AI pays off quietly. By learning from past performance and current job signals, AI can forecast where you’re likely to run short on labor or equipment, then recommend cost-effective shifts, like moving a crew earlier to protect a handoff, delaying non-critical work to avoid trade stacking, or reallocating supervisors to the riskiest zones.

Where teams see the biggest benefits

This is where the impact compounds, because it’s the work that normally stays hidden until it becomes expensive.

- Change control: AI helps spot scope creep earlier by linking RFIs, submittals, field notes, and change signals to budget and schedule impact.

- Procurement and long-lead forecasting: AI is great for predicting which packages are likely to slip based on vendor history and approvals latency, then pushing escalation earlier.

- QA/QC and rework prevention: AI-assisted inspection from photos, punch trend analysis, and pattern detection in nonconformances tie directly to repair costs and schedule stability.

20 examples of AI in construction project management

Forget the sci-fi version of AI for a minute. For construction projects, it appears as a series of small, targeted upgrades that smooth out coordination and make progress easier to demonstrate. The examples below reflect where AI adoption is already paying off on real job sites.

1. Cross-team coordination and workflow control

Schedules don’t blow up all at once; they slowly leak momentum in the gaps between handoffs. AI improves coordination by turning scattered requests and hidden approvals into a trackable flow, so issues land with the right team and work stops dying in the gaps between handoffs.

Wrike helps construction teams standardize intake and coordination, so work stays visible across owners, designers, and trades. With AI support, teams can reduce manual follow-up by automating repetitive steps and preventing risks and blockers from being lost in email.

2. Surface construction project risk earlier

Ever wish your risk log updated itself? Autodesk’s Construction IQ uses built-in machine learning to scan project data and flag high-risk areas across cost, schedule, quality, and safety.

It’s one of the biggest names in design and construction software, known for tools like Revit, AutoCAD, and the Autodesk Construction Cloud. AI features like Construction IQ, Autodesk Assistant, photo auto-tagging, and predictive risk scoring help teams sift through drawings, photos, and project data to surface issues earlier and reduce rework.

3. Workflow automation for RFIs, submittals, and schedules

On most jobs, the real bottleneck isn’t steel or concrete — it’s the paperwork stuck in someone’s inbox. AI can draft first-pass RFIs, pull specification references, route submittals, and keep schedule updates moving with fewer manual touchpoints.

Procore AI does just that, and it also uses an agent builder for creating agents that handle tasks like RFI drafts or managing submittals.

4. Complex document analysis with AEC-focused agents

Specifications are where half the project lives and most of the landmines hide. AI can break them open, extract requirements, and surface the details that actually affect scope and compliance.

Egnyte’s AEC AI agents are explicitly aimed at the specs and compliance bottleneck, including a “specifications analyst” that turns large spec docs into queryable source data with filters and the ability to aggregate extracted data across spec divisions.

5. Copilots for superintendents and project managers

Document-grounded copilots help supers and PMs get instant answers from drawings, specs, and submittals without digging through files. A tool in this category is Trunk Tools, which is built for jobsite speed.

Ask a question in plain language, get an answer grounded in your project documents with links back to your documents. Coverage includes Q&A and workflows, such as comparing a submittal against specifications, which is exactly the kind of time-sink superintendents hate.

6. AI quantity takeoffs and estimating from plan sets

Takeoffs are where time disappears quietly. When you need fast numbers, AI can scan plan sets and generate early quantities that help preconstruction teams assess feasibility without losing a week to manual takeoffs.

Civils.ai pitches itself as AI for PDF/CAD takeoffs, estimation, and quantity surveying, with additional positioning around extracting data from drawings like schedules, notes, tables, and specifications. It’s designed to compress the takeoff cycle when you need early numbers quickly.

7. Automating site and design workflows

Site design has plenty of creativity. Plan production and annotation are not where anyone wants to spend it. Bentley’s OpenSite+ integrates generative AI into civil site design, automating drawing annotation and plan production with copilot-style assistance that leverages your own documents and models for faster edits and answers.

8. Cloud-based project estimation

Rather than relying on one baseline, AI tools can generate alternative sequences, test constraints, and reveal which options hold up best once work begins.

ALICE Technologies is specifically designed to explore various scheduling scenarios, optimizing and mitigating project risks. It focuses on automated scenario exploration for bidding and execution, as well as recovery scenarios in the event of changes.

9. Unified project and cost intelligence

On complex construction projects, the story isn’t always consistent. Now, PMs can complete their projects on time and on budget with real-time insights and AI-driven automation.

One example is Zepth, which is a unified system across projects, financials, procurement, and field operations, connected via dashboards and automated reporting, and it also markets an “AI Copilot” style layer for conversational access to predictive insights.

10. AI-powered drones for site monitoring

Recurring capture doesn’t need a person on site. AI-powered drones can fly predetermined paths and gather detailed imagery for inspections and progress verification. Skydio is a good example of what AI drones look like when they’re built for something other than cool aerial shots.

They position their drones strategically, capturing inspection data early and often, so you can identify issues before they escalate into rework.

11. Robotic on-site data collection

Some robots can run the same path every day, capturing accurate data in conditions that would be tedious or unsafe for humans to work in. Spot is an example of a one-off site scan.

It’s a mobile robot designed to move through dynamic sites and capture progress data autonomously with more frequent, repeatable scans and less variation. Plus, if your virtual design and construction team is stretched thin, this is the kind of tool that scales site capture without scaling headcount.

12. Making field data actionable

Field data is valuable. It’s also messy, nonstop, and annoying to translate into decisions. Trimble is using AI to speed up estimating and takeoff (like AI recognition that detects and counts symbols on drawings) and to automate reality-capture processing in the field, including point cloud segmentation/classification and feature extraction.

13. PPE compliance and hazard detection

Safety issues rarely announce themselves; instead, they creep in through tiny lapses and bad timing. AI vision systems can monitor live camera feeds and identify safety issues, such as missing PPE, unsafe proximity to equipment, or hazardous conditions, long before they escalate into incidents.

For example, viAct PPE Detection applies computer vision to video feeds to flag missing PPE, such as helmets and vests. It makes compliance monitoring more consistent, especially on large sites where supervision cannot be everywhere at once.

14. Construction contract review and risk spotting

Contract language shapes the entire project. AI can quickly read large agreements, highlight risky clauses, and help teams understand their obligations before they become expensive.

Document Crunch is purpose-built for construction document review, positioned to expedite contract reviews and manage compliance with construction-specific outputs. This is the kind of tool that helps you understand exposure before a problem becomes a dispute.

15. Claims analysis and drafting support

In the event of a dispute, AI can pull months of project documentation into a clear, defensible claim that stays tightly grounded in the actual record.

ClaimMaster.ai positions itself as construction-specific AI for claims, including assistants for delay, quantum, and legal work, and emphasizes compliance and data handling in its materials. It’s aimed at making claims work more consistently and less dependent on whoever can write the longest email.

16. Progress-to-plan tracking from site walks

AI progress tracking turns routine site walks into measurable percent-complete data by comparing installed work to the model or schedule. One example is Buildots, which is built around hardhat-mounted 360° cameras during routine site walks, then uses computer vision to track progress and compare it to the plan.

You capture 360° footage, it recognizes what’s installed, then it’s brutally honest about what’s missing, where, and how that maps back to the plan.

17. Always-on coaching and operational support

What do you lean on when the day-to-day grind of running construction projects starts swallowing the bigger business decisions? Some AI platforms are trained on construction business playbooks, so they can flag operational blind spots and give leadership a clearer read on decisions when they need a second brain.

For example, APB Brain is positioned as an always-on assistant trained on over a decade of APB content, like action plans, checklists, templates, and coaching materials, tailored specifically to residential building company owners.

18. Automated construction layout

Layout doesn’t have to be a tape measure and a leap of faith anymore. Instead of drawing lines by hand, robotic layout systems can print BIM-based layouts directly onto the slab with high accuracy, reducing clashes and layout-related rework.

Dusty’s FieldPrinter is one example of this in action. It’s an autonomous layout robot that prints BIM-based layout at full scale on the jobsite floor. The interesting part for project managers is that it tightens handoffs between design and install, and it reduces layout rework that shows up later as trade friction and corrective work.

19. 3D drone mapping software

For earthwork, a single drone flight can turn the site into a living 3D model, giving you up-to-date volumes and movement at a glance and tightening the link between what moved and what it cost.

Propeller is built for measuring dirt, literally. It turns drone flights into 3D terrain you can measure, giving you current numbers on how much earth has actually moved, so earthworks progress and pay quantities stop relying on slow survey cycles and guesswork.

20. Robotics for autonomous trenching

Repetitive excavation doesn’t always need a full crew. AI-powered robots can cut trench lines to plan while quietly logging production and as-built information in the background.

One example is Built Robotics. It retrofits excavators with GPS-guided automation and onboard sensing so they can cut trench lines to plan while recording the work as they go, giving you consistent output and a usable production record.

The future of AI in construction

Grand View Research estimates that AI in the construction industry will grow to just under $17 billion by 2030, which is a fancy way of saying more state-of-the-art AI systems are about to show up on more job sites. AI in manufacturing is already using similar technologies, so construction is effectively watching a preview of where its own tools are headed next.

If you want AI to do real work for you, start by making the workflow predictable with Wrike AI. Wrike provides construction managers with a single, grounded platform to manage a job, where tasks, conversations, and documentation remain linked, and the system surfaces what needs your attention, rather than requiring you to dig for it.

FAQs: Using AI in construction

How is AI used in construction?

AI is used in a multitude of ways, such as drone-based site capture and surveying, robotics for layout and repetitive tasks, computer vision to monitor construction sites for safety and progress, and automation for estimating, scheduling, and document work like RFIs, submittals, and contracts.

What types of AI technologies are commonly used in the construction industry?

Machine learning shows up in forecasting and risk detection, computer vision interprets site imagery for safety and progress, and natural language models handle the heavy document work that slows teams down. Optimization engines round it out by stress-testing schedules and resources, so plans hold up better once the job starts moving.

Can ChatGPT read construction plans?

It can summarize plan notes and answer questions from uploaded plan text, but it’s not a substitute for plan review or code-critical decisions without a human and the right tools checking the output.

Is AI replacing human workers in construction?

No, construction still runs on craft and people who can coordinate in real time, and AI isn’t replacing project managers either. Although AI is getting good at handling repeatable tasks and tightening processes, the human side is still what makes construction projects work.

How do you start using AI in construction without a big software overhaul?

Pick one pain point with clear ROI, like RFI drafting and document search or progress capture, and pilot it with one project team before scaling.

What are the biggest risks of using AI on construction projects (privacy, liability, hallucinations)?

The real risks are mundane things, such as leaking sensitive project data into tools you don’t control and blurring responsibility when a bad suggestion quietly influences a cost, scope, or safety decision. Hallucinations make it worse, because the system can sound confident while being completely wrong, so anything high-stakes still needs a human who checks the evidence.