Key takeaways:

- What are the main challenges in manufacturing today? Increasing complexity, higher customer expectations, data silos, manual tasks, and supply chain disruptions hinder innovation.

- How can AI improve manufacturing? AI enhances decision making and operational efficiency by analyzing data for predictive maintenance and demand forecasting.

- Why is a strong data foundation crucial? A solid data foundation ensures accurate, accessible, and actionable insights necessary for effective AI integration and process optimization.

- What is collaborative work management? Collaborative work management unifies people, processes, and information, eliminating silos and creating a reliable source of truth for better decision making.

- How can organizations begin their transformation? Conduct a data audit, centralize critical information, pilot AI initiatives, and foster a culture of continuous improvement.

Manufacturing is at a crossroads. The pressure to innovate, accelerate product development, and deliver higher value with fewer resources has never been greater. Yet, for many organizations, the promise of artificial intelligence (AI) and digital transformation remains just out of reach. Why? Because the true power of AI in manufacturing can only be unlocked by building a strong data foundation.

In this post, I’ll explore the challenges holding manufacturers back, the promise of a data-driven future, and practical steps to get started. Along the way, I’ll highlight how industry leaders are transforming the way products are designed, built, and delivered by unifying data and collaboration.

The challenge: Manufacturing’s new reality

Let’s set the stage. Manufacturing has always been about solving problems — making things better, faster, and more efficient. But the problems we face today are different from those of the past. Global supply chains are more complex, customer expectations are higher, and the pace of change is relentless. At the same time, new technologies are opening up incredible opportunities. The question is: how do we harness these opportunities while overcoming the challenges?The hidden cost of inefficiency

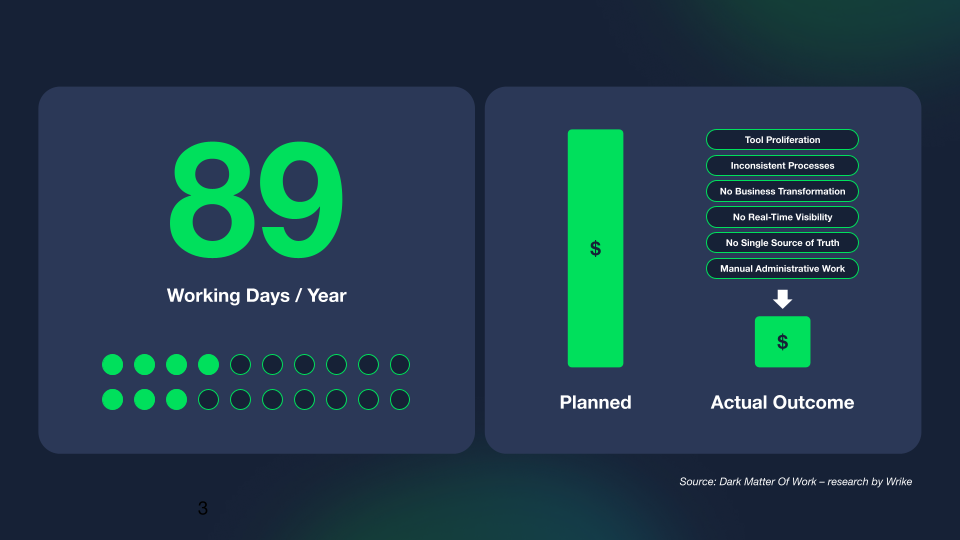

Let’s start with a staggering number: 89 working days per year. That’s how much time the average worker wastes on non-value-added tasks — chasing down information, digging through emails, and repeating work that’s already been done. For large enterprises, this adds up to millions of dollars in lost productivity every year.

But the cost isn’t just financial. Wasted time leads to project delays, employee burnout, and missed opportunities for innovation. According to research from Wrike’s “Dark Matter of Work” report, knowledge workers waste nearly 14 hours per week on duplicated work and searching for information. For a typical large organization, this can cost over $60 million per year.

The pace and complexity of change

The challenges are coming at us faster than ever: supply chain disruptions, new market entrants, shifting consumer expectations, and a level of uncertainty that seems to be the new normal. The manufacturing sector is no stranger to change, but these challenges are unprecedented. Here are just a few of the hurdles organizations face:

- Increasing complexity and speed: Product lifecycles are shorter, and customer expectations are higher. Manufacturers must innovate faster than ever to stay competitive.

- Pressure to innovate and adapt: New market entrants and shifting consumer demands require constant adaptation.

- Data silos and disconnected teams: Information is often trapped in separate systems, making it difficult to get a clear, real-time view of operations.

- Manual administrative work: Despite advances in automation, many processes are still bogged down by manual tasks and inconsistent workflows.

- Lack of real-time visibility: Without a single source of truth, it’s hard to make informed decisions quickly.

- Supply chain disruptions and uncertainty: Tariffs, global events, and market volatility are now part of daily life.

These challenges aren’t just operational — they’re strategic. The organizations that can overcome them will be the ones that thrive in the years ahead.

The reality of product lifecycle complexity

But wait — there’s more! Manufacturing, more than other industries, can be particularly complex. When talking to our customers about the product lifecycle, even though it’s a “cycle,” we often present it in a linear series of stages from initial concept through support. It’s a pretty standard Waterfall framework. But anyone who’s been involved in product development knows it’s never that simple. There’s a lot of back-and-forth, a lot of iteration, and a lot of intricacies at every stage.

What makes it even more challenging is the sheer number of departments and stakeholders involved. From R&D to design, engineering, manufacturing, quality, and support — everyone has a role to play, and everyone has questions that need answering. To manage this complexity, manufacturers have adopted specialized tools like PLM, ERP, and MES. These systems are great within their own silos, but when information needs to move between teams, things can get sticky.

That’s where the real gaps — and the real opportunities — lie. This is where information between teams tends to get shared most commonly via spreadsheets and email. We’ve all been there — trying to track down the latest version of a file, or searching through endless email threads for a critical update. It’s a system that’s prone to human error, miscommunication, and lost information. The consequences can be serious: production delays, missed deadlines, dissatisfied customers, and, ultimately, a hit to your bottom line. But the good news is … it doesn’t have to be this way.

Evolution of work management

Let’s take a quick trip down memory lane. Remember when work looked like this? Papers everywhere, sticky notes, and that one whiteboard in the corner that hasn’t been erased since 2003? Fast forward to today, and things look a lot cleaner — at least on the surface.

A quick note on Wrike’s journey: Wrike has been at the forefront of this evolution for nearly 20 years. We started as a project management platform, revolutionary at the time for moving teams beyond spreadsheets. In the 2010s, we realized that plans alone weren’t enough; collaboration and shared responsibility became key. Now, in the 2020s, we’re focused on bringing people, process, and product data together in one place, enabling teams to work smarter, not harder.

But is it fast enough? Let’s be honest: a big chunk of our workflows still lives in a dusty notebook, or worse, in John’s head. If you want to know how anything really works, you just ask John. He’s been here for 40 years … but he’s retiring in 2027.

The reality is, while our desks have gotten tidier, our work has gotten more complex. We’ve moved from siloed project management to digital collaboration, and now to integrated, automated workflows powered by AI and data. The challenge now is to make sure that all of this knowledge and information is captured, shared, and used to drive better decisions — not just stored away in someone’s memory or a forgotten file.

The promise: AI, digital twins, and the power of a unified data foundation

So, what’s the way forward? The answer lies in harnessing the power of AI, digital twins, and, most importantly, data. But here’s the catch: AI and digital twins are only as effective as the data they’re built on. Without a strong data foundation, even the most advanced technologies can’t deliver real value.

AI: Smarter, faster decisions

Artificial intelligence is already transforming manufacturing. From predictive maintenance to demand forecasting, AI can analyze vast amounts of data and surface insights that would be impossible for humans to find on their own. This leads to smarter, faster decision making at every level of the organization.

Digital twins: Real-time simulation and optimization

Digital twins are virtual replicas of physical processes, products, or systems. They allow manufacturers to simulate and optimize operations before making changes in the real world. This reduces risk, accelerates innovation, and helps teams identify the best path forward.

Data quality and accessibility

Data is the fuel that powers modern manufacturing. But it’s not enough to simply collect data — you need to ensure it’s accurate, accessible, and actionable. When data is centralized and connected, it becomes a powerful driver of innovation. If your critical business data is scattered across spreadsheets, emails, and tribal knowledge, it’s locked away and useless. The first step to harnessing the power of these technologies is to build a solid data foundation.

Collaborative work management: The key to a strong data foundation

That’s where collaborative work management (CWM) comes in. CWM is a strategic approach to unifying people, processes, and information in a single, centralized platform. By bringing all your critical data together, CWM eliminates silos and ensures that everyone is working from the same source of truth. This centralization is essential for effective work management, especially as projects become more complex and timelines get tighter.

But the benefits go beyond just visibility and coordination. When you centralize your data with a work management platform, you’re also laying the groundwork for a strong data foundation. This creates a reliable source of truth that can be analyzed for insights, used to automate routine processes, and even fed into AI engines to predict risks or optimize resource allocation. In other words, CWM prepares your organization for the future.

At Wrike, we’ve seen firsthand how CWM empowers manufacturers and enterprises to orchestrate their work, break down barriers, and usher in new levels of productivity and innovation.

Real-world examples: Industry leaders building their data foundations

Leading manufacturers are already seeing the benefits of a unified data approach.

- Siemens, for example, streamlined collaboration across 20+ countries and achieved a 10% productivity boost by centralizing project management and automating workflows.

- NVIDIA transformed its global operations by moving project management, resource scheduling, and real-time data tracking into a single platform, enabling teams to spot and solve issues before they escalate.

- Jaguar Land Rover accelerated its product lifecycle and saved over £1 million in just six months by making Wrike the go-to tool for cross-departmental planning and feedback.

These organizations prove that building a strong data foundation is a practical, achievable strategy that delivers measurable results. Read more about these success stories on Wrike.com.

Building a future-ready organization: The data foundation pyramid

Let’s talk about what it really takes to build a future-ready organization. Picture a pyramid:

- At the base: Data identification and access. Know exactly where your data lives — across teams, systems, and even those hidden spreadsheets — and make sure you can reliably access it when you need it. Without this foundation, everything else is built on shaky ground.

- Next layer: Data cleaning and organization. Ensure your data is accurate, consistent, and structured in a way that makes it usable. Even the most advanced technologies can’t deliver value if they’re working with incomplete or messy data.

- Following layer: Apply your organized data to business processes. This is where you begin to see tangible improvements, such as streamlining workflows, reducing manual effort, and driving efficiencies across the organization.

- At the top: With a solid data foundation in place, you can seamlessly integrate advanced technologies like AI, digital twins, and analytics. At this level, these tools work together to deliver powerful insights, automate complex decisions, and optimize operations in ways that simply weren’t possible before.

The people side of data: Connecting the value chain

It’s important to recognize that not all data is created equal — or equally accessible. Many manufacturers have made great strides on the machine-driven side, using sensor data, automation, and real-time analytics to optimize production. But people-driven data — design, engineering, and R&D — is often scattered, siloed, or locked away in spreadsheets and personal knowledge.

Think of your data strategy like a puzzle. The machine-driven pieces are critical, but they only form part of the picture. To uncover the full potential of your data foundation, you need to connect both sides.

Let’s simplify your value chain and split it into two parts: design/engineering and manufacturing. Each relies on a combination of people and machine efforts. They need to work on aligned schedules and complete their jobs as planned, so you can bring your product to market on time and ultimately make it profitable. Given the pace of change, it’s going to get increasingly difficult to do that without optimizing your people workflows. And that’s an opportunity that, for most, is untapped.

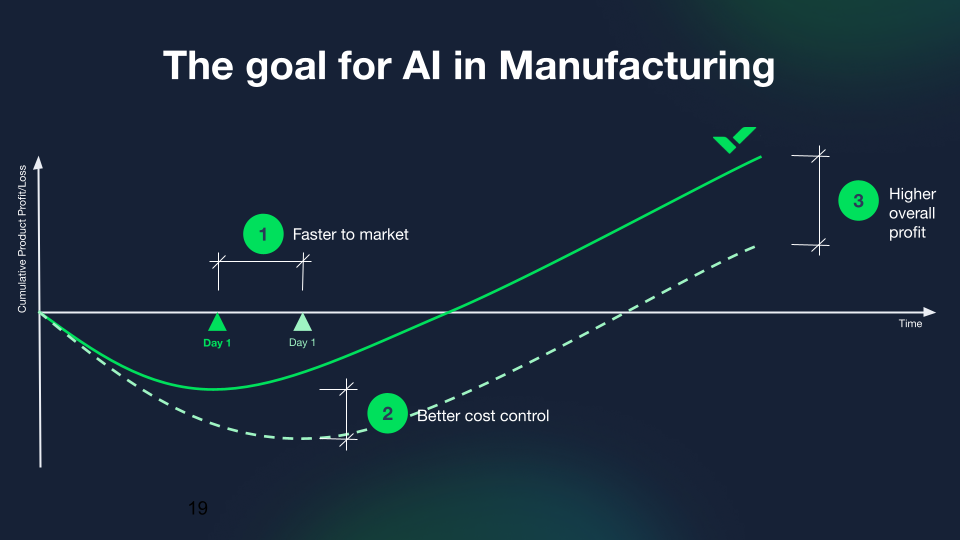

The real role of AI: Accelerating time to value

And that’s the real role of AI in all of this — it shouldn’t be only to help you write better emails or take meeting minutes; it should enable you to get your product to market faster, control costs more effectively, and achieve higher overall profit.

Imagine if we could unlock and centralize all of that data. What if every stakeholder, from R&D to production to marketing, had real-time access to the latest information, feedback, and insights? What if we could use AI and automation to surface the most relevant data, identify bottlenecks, and suggest solutions before problems even arise? That’s the real opportunity here. That’s the real competitive advantage: innovation at the speed of your ideas, powered by a unified data foundation.

Getting started: Practical steps for manufacturers

So, what can you do right now to start your own transformation journey?

- Take a hard look at your data

Identify how key workflows are planned, executed, and reported on. Conduct a data audit and assess data quality and accessibility. Centralize your critical business information in a platform that can enhance its value, whether that’s Wrike or another system. - Pilot AI or digital twin projects in high-impact areas

Select a process or product line with clear pain points or bottlenecks. Define success metrics and desired outcomes. Launch a small-scale pilot, monitor results, and iterate. - Don’t forget your people

Create a culture of continuous improvement and digital literacy, empowering your teams to embrace change.

The future of manufacturing belongs to those who can harness the power of AI — and it all starts with data. From my own experience working with teams across the industry, I can confirm that ditching spreadsheets and moving to a centralized platform that makes your data accessible not only to your teams but also to your AI can be the key to transforming your entire business. You’re not just making processes more efficient, you’re giving people the power to focus on the work that really matters. And that’s what Wrike is all about — helping you do the best work of your life.

Ready to take the first step? Explore how Wrike can help your organization build its data foundation and unlock the full potential of AI in manufacturing. Reach out to learn more about how we’re helping industry leaders transform their operations for the future.